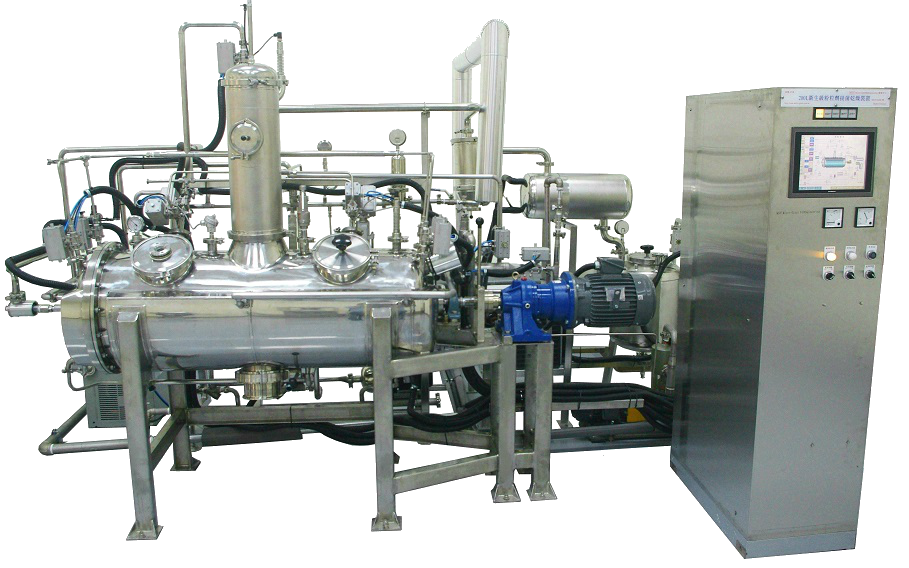

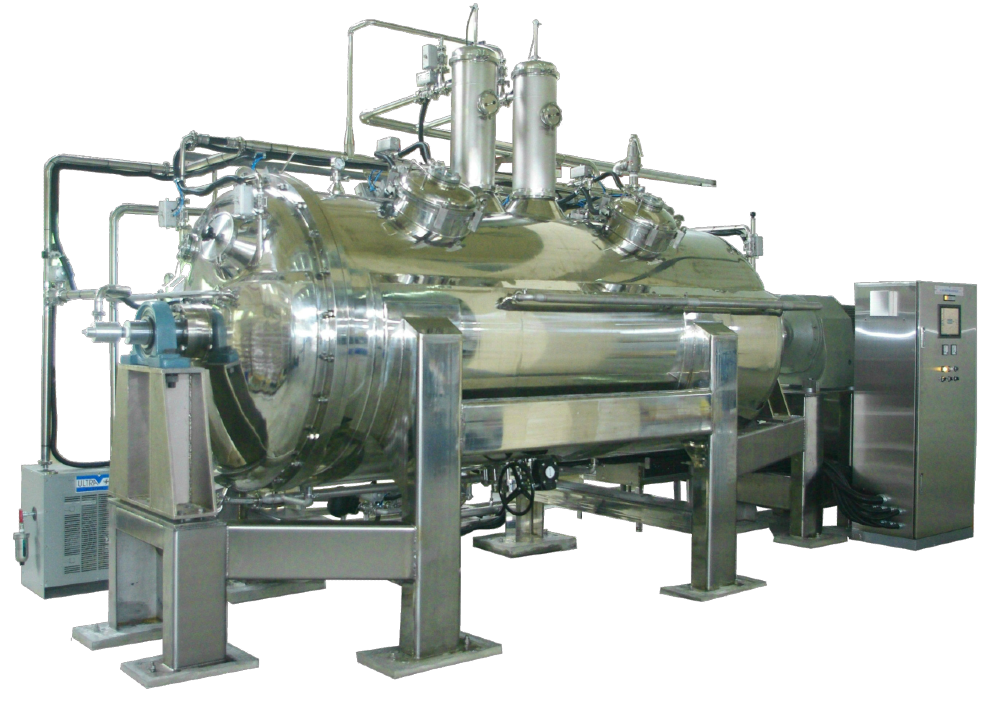

Solid state bioreactor/fermenter (SSF series) 200L ~5,000L for microbial cultivation - automatic control

Factory production, SIP system

Specification

| SSF series |

|

| |||||||||||

Model | MGB-SSF200 | MGB-SSF500 | MGB-SSF1k | MGB-SSF2k | MGB-SSF3k | MGB-SSF5k | |||||||

| Total volume | 200L | 500L | 1,000L | 2,000L | 3,000L | 5,000L | |||||||

| Working volume (note 2.) | 120L | 300L | 600L | 1,200L | 1,800L | 3,000L | |||||||

| Operating speed | 8~85 rpm | 6~65 rpm | 5~50 rpm | 4~40 rpm | 3~35 rpm | 3~30 rpm | |||||||

| Frequency converter (with agitation current limit display and control) | |||||||||||||

| Design pressure and material | Vessel 2kg/cm2 (SUS316L),jacket 3kg/cm2 (SUS304) | ||||||||||||

| Operating pressure | Sterilization 1.2~1.5 kg/cm2, culture 0.1~0.8 kg/cm2. | ||||||||||||

| Pressure vessel certified | ASME U stamp | ||||||||||||

Function and processing description | Put raw material: put matrix through hand hole (man hole)(can put two or more than two kinds of material to do mixed formulation). Hunban: in the beginning of operation stage can use intermittent or continuously to mix the material evenly(also can break big nodules). Cooking/sterilization: put the matrix after flip and stir moderately and use clean steam through vessel and jacket to do steam cooking and sterilization121℃~125℃. Inoculation: after sterilization, spray the broth on solid matrix to mix evenly. Culture: set appropriate growth temperature, humidity control, intermittent frequency, gas change/air flow rate, automatic fermentation control during culture cycle. Discharge: after drying, the solid product will discharge through the large diameter butterfly valve . | ||||||||||||

| Control box | |||||||||||||

- Stainless steel waterproof control box,15"TFT LCD HMI with 65,535 colors, PLC control unit, graphic dynamic equipment monitoring operation screen, parameter setting screen. - Online monitoring condition trend analysis. | |||||||||||||

| Control functions | Sterilization:automatic SIP process (vessel; medium sterilization) | ||||||||||||

| Temperature, agitation, air flow, pressure, agitate current control, humidity control | |||||||||||||

| On/Off intermittent flip | |||||||||||||

| Document | material certificate, production chart, welding record, pressure test report, operation manual, equipment outline chart, P&ID, layout, electrical map …etc. | ||||||||||||

| Optional |

| ||||||||||||

Note 1:This culture equipment, the solid matrix used for culture needs to be shear force resistant and the strain must be allow to flip (turn over).

Note 2:Working volume means the biggest volume(including expansion amount) during the whole process expressed in liter. Due to different matrix and strain characteristics, the amount of operation needs to be adjusted appropriately.

Note 3:Detailed specification subject to formal quotation.